The use of medical-grade molds is becoming increasingly important in the healthcare sector. These innovative molds play a significant role in assisting healthcare professionals in delivering patient care and enhancing overall results. With progress in technology and materials, medical-grade molds have undergone development over time. This article delves into the advantages and uses of these molds, illustrating how they contribute to improving patient outcomes.

Improved Precision and Accuracy

A key benefit of utilizing medical grade molds is their capacity to offer precision and accuracy during medical procedures. Whether it involves prosthetics or personalized orthopedic implants, these specialized molds enable a fit and alignment tailored to each patient’s specific requirements. The accuracy provided by these molds substantially reduces the risk of complications that may arise from generic devices.

Tailored for Patient Comfort

Medical grade molds empower healthcare professionals to develop customized solutions that are specifically designed for patients’ comfort levels. Through measurements obtained via 3D scanning or digitization methods, manufacturers of medical-grade molds can create products that enhance patient comfort while ensuring functionality. This high degree of customization ensures that patients receive treatments and interventions that address their needs effectively.

Enhanced Infection Prevention

In healthcare settings, maintaining infection control is crucial, and having equipment that reduces contamination risks is essential. The use of medical-grade molds plays a role in addressing this concern as they seamlessly align with infection control practices. Molds crafted from materials further lower the chances of cross-contamination, enhancing safety during surgical procedures and other medical interventions.

Faster Recovery Process

Research has indicated that the application of medical-grade molds can speed up the healing process for patients undergoing treatments and procedures. The precise fitting provided by these molds aids in wound healing by alleviating pressure points, minimizing tissue damage, and enhancing blood circulation around the area. Consequently, patients experience accelerated recoveries with decreased operative pain and discomfort levels.

Economical Solutions

Integrating medical grade molds into patient care strategies enables healthcare providers to achieve cost-effective solutions. While the initial investment in these specialized molds may appear higher compared to alternatives, their long-term advantages surpass the costs. Enhanced patient outcomes result in complications, shorter hospital stays, and reduced expenses for actions often needed with generic devices. Additionally, using medical-grade molds helps reduce the need for revisions or replacements due to functionality issues.

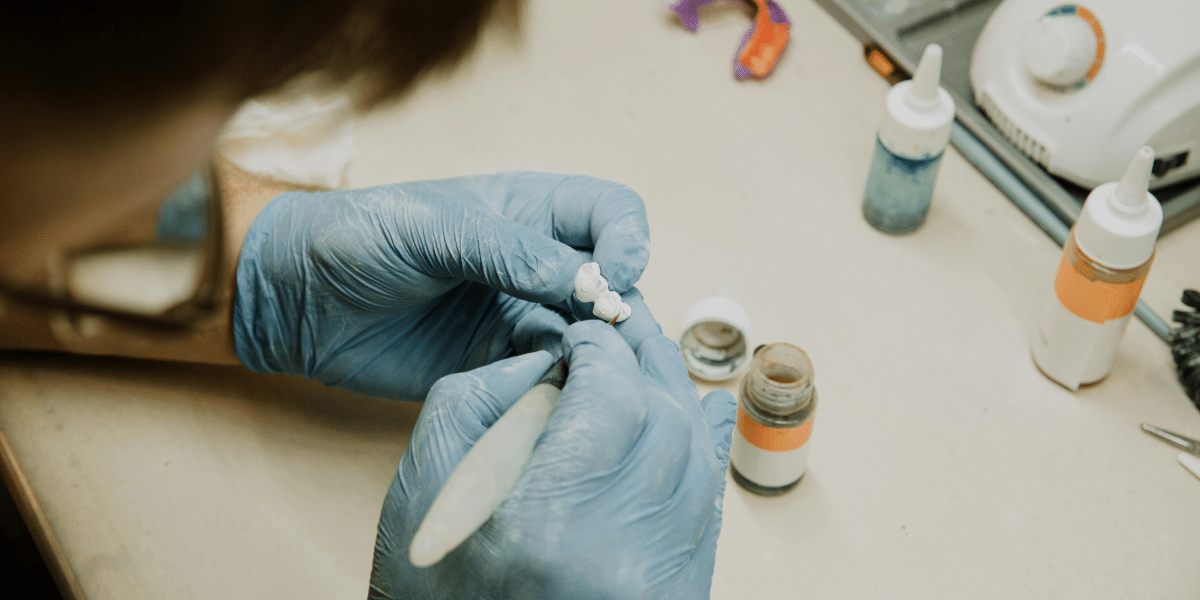

A Broad Range of Uses in Medical Fields

Medical grade molds are utilized in a variety of healthcare specialties, showcasing their adaptability. They are suitable for a range of disciplines such as dentistry, orthopedics, prosthetics, and even sectors like sports medicine and veterinary care. These molds can be customized to meet the needs of patients of older age or anatomical requirements.

Advancements in Technology Driving Progress

The continuous evolution of technology is shaping the landscape of medical-grade mold production. Innovations like 3D scanning for measurements and the use of cutting-edge materials for durability and infection control properties contribute to enhancing patient outcomes. Collaboration between mold manufacturers and healthcare institutions plays a role in driving innovation by incorporating input from frontline medical professionals.

Enhancing Functionality of Prosthetics Long Term

Medical-grade molds improve functionality, particularly in the field of prosthetics. A fitting prosthetic socket is crucial for individuals with limb loss as it impacts comfort, mobility, and overall quality of life. These molds have transformed the creation process by enabling customizations and precise fittings for socket designs.

Moving Away from Traditional Methods

Previously, creating prosthetics involved processes like making physical plaster casts, which often resulted in inconsistencies and discomfort for patients. However, thanks to the improvements in 3D scanning technology, healthcare professionals can now digitally acquire measurements, ensuring a perfect fit right from the beginning.

Summary

The use of medical grade molds marks an advancement in improving outcomes in the healthcare sector. The accuracy, customization options, infection control features, faster healing processes, cost-effectiveness, and versatility across specialties are key drivers behind their increasing adoption in different clinical environments. As technology progresses rapidly with enhancements across medical fields that demand customized solutions, it is clear that medical grade molds will play a crucial role in shaping future healthcare delivery models with a focus on achieving optimal patient results.

Published By: Aize Perez