In the realm of heavy-duty applications, durability is paramount. As professionals navigate the challenges of maintaining equipment and infrastructure in demanding environments, they often seek innovative solutions to enhance longevity and performance. Solvents offer powerful chemical properties that contribute to durability across industries. These versatile substances support cleaning, degreasing, providing protective coatings, and improving material properties. This article explores how solvents are being utilized to extend the life of heavy-duty equipment, reduce maintenance costs, connect with a reputable Heptane supplier, and improve overall efficiency. Discover the potential of these chemical allies in achieving enhanced durability.

Heavy-Duty Applications Require Durable Products

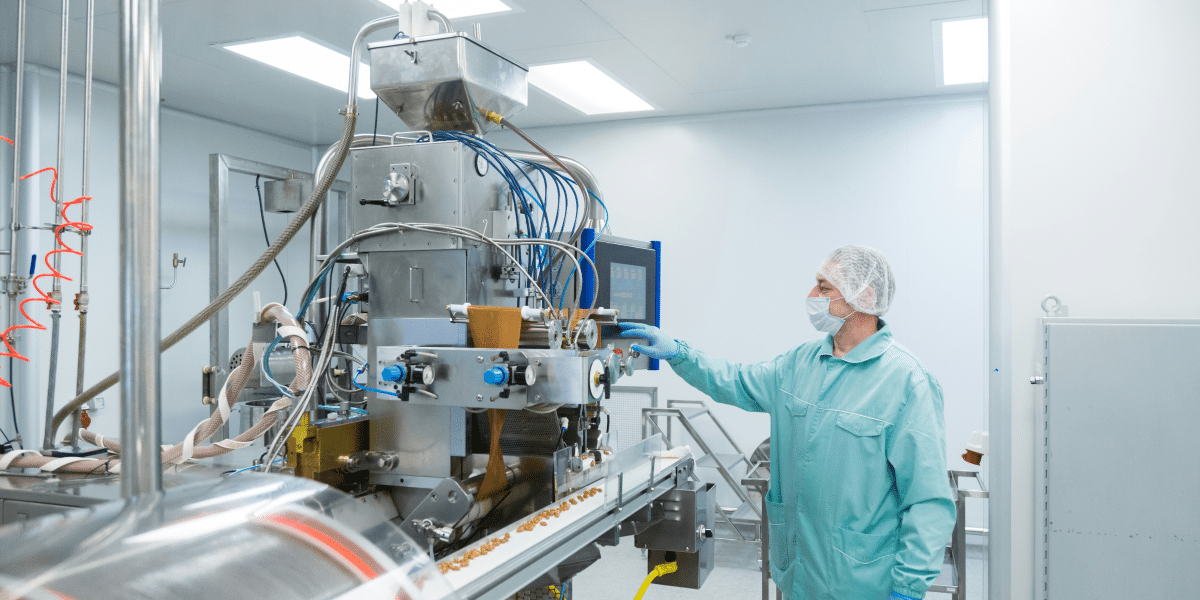

Heavy-duty industrial and commercial operations demand products that can withstand extreme conditions and prolonged use. These applications often involve harsh environments, intense physical stress, and exposure to corrosive substances. The durability of materials and equipment used in these settings is essential for efficiency, safety, and cost-effectiveness.

Challenging Environments

Heavy-duty applications typically operate in environments that test materials to their limits. From construction sites exposed to the elements to manufacturing plants with high temperatures and chemical exposure, these settings require products that can maintain integrity under duress. Durability in these contexts isn’t just about longevity; it’s about consistent performance in the face of relentless challenges.

The Cost of Failure

When products fail in heavy-duty applications, the consequences can be significant. Industrial-process downtime can lead to substantial financial losses, while equipment failures in critical infrastructure could pose safety risks. This underscores the importance of using materials and products specifically engineered to endure the rigors of these demanding applications.

Innovations in Durability

Manufacturers are innovating constantly to meet the needs of heavy-duty applications. Advanced materials science has developed new alloys, composites, and coatings that provide excellent resistance to wear, corrosion, and fatigue. These advancements may incorporate nanotechnology and smart materials to adapt to changing conditions, further enhancing durability and performance in the most challenging environments.

By prioritizing durability, industries can ensure reliability, reduce maintenance costs, and improve operational efficiency. As this article further explores, solvents contribute significantly to enhancing these durable solutions in demanding settings.

How Solvents Enhance Durability

The role of solvents in durability cannot be overstated. These chemical agents are essential in improving the longevity and resilience of various materials. Let’s explore how solvents contribute to increased durability in industrial settings.

Improved Coating Adhesion

Solvents are instrumental in enhancing the adhesion of protective coatings to surfaces. By dissolving and carrying coating materials, they enable better penetration into substrate pores and crevices, which results in a stronger bond between the coating and the surface. This bonding improves resistance to wear, corrosion, and environmental stressors.

Enhanced Material Compatibility

In many applications, different materials must work together seamlessly. Solvents aid in material compatibility, promoting cohesion between diverse substances. They can temporarily soften certain materials, allowing for better integration and reducing the risk of separation or delamination. This improved cohesion translates to enhanced durability in composite structures and multi-material assemblies.

Efficient Cleaning and Maintenance

Durability isn’t solely about initial strength; it also involves maintaining performance over time. Solvents are effective in cleaning and maintenance processes, removing contaminants, oils, and debris that can compromise material integrity. Using the right solvents for regular cleaning can help extend equipment lifespan, preserving durability in industrial environments.

Customized Formulations

The versatility of solvents allows manufacturers to tailor solutions to specific challenges. By carefully selecting and blending different solvents, manufacturers can address unique environmental stressors, chemical exposures, or mechanical demands. This customization ensures materials and coatings are prepared to endure the exact conditions of heavy-duty applications, optimizing longevity and performance.

Popular Solvents Used in Heavy-Duty Applications

Certain solvents are recognized for their performance and versatility in heavy-duty applications. These chemical agents play a pivotal role in durability and efficiency across various industrial sectors.

Acetone: The Versatile Powerhouse

Acetone is widely used in heavy-duty applications for its rapid evaporation rate and strong dissolving properties, making it ideal for cleaning and degreasing metal surfaces. Industries such as automotive and aerospace use acetone to prepare surfaces for painting or bonding, ensuring optimal adhesion and longevity of protective coatings.

Toluene: The Tough Contender

Toluene excels at dissolving oils, resins, and rubber-based compounds. Its high solvency power makes it an effective choice for industrial cleaning and as an ingredient in high-performance coatings and adhesives used in construction and manufacturing.

Xylene: The Slow and Steady Worker

With a slower evaporation rate than acetone, xylene is particularly useful in applications requiring extended working time. This solvent is frequently utilized to formulate protective coatings for machinery exposed to harsh environments, contributing to more uniform and resilient finishes.

Methyl Ethyl Ketone (MEK): The Precision Player

MEK offers a balance of strength and control. Its moderate evaporation rate and excellent solvency make it ideal for precision cleaning operations. MEK is widely applied in electronics for removing flux residues and preparing surfaces for intricate assembly processes.

Leveraging the unique properties of these solvents can help industries enhance the durability and performance of heavy-duty applications, promoting longer-lasting and more reliable products.

Finding a Reputable Heptane Supplier

Sourcing high-quality heptane for heavy-duty applications requires partnering with a trustworthy supplier. A reliable vendor not only ensures product quality but also provides valuable support. Here’s what to consider when selecting a heptane supplier:

Evaluate Product Quality and Purity

The effectiveness of heptane in enhancing durability depends on its quality. Choose suppliers who offer high-purity heptane (ideally 99% or above). Request certificates of analysis and ask about their quality control processes.

Assess Industry Experience and Expertise

Select suppliers with a proven record in the chemical industry, particularly in solvents for heavy-duty applications. Experienced vendors offer insights into proper handling and application techniques and can answer technical questions related to safety protocols.

Consider Supply Chain Reliability

Supply chain stability is crucial. Evaluate suppliers based on their ability to maintain consistent inventory levels and meet delivery deadlines. Inquire about sourcing practices and contingency plans to manage potential disruptions.

Check for Regulatory Compliance

Ensure the chosen supplier adheres to industry regulations and environmental standards. They should provide documentation, such as safety data sheets (SDS) and certifications. Compliance ensures safety and protects against legal risks.

Final Thoughts

Solvents play a valuable role in enhancing durability across heavy-duty applications. Partnering with a reliable Heptane supplier and using appropriate solvents can improve the performance and lifespan of coatings, adhesives, and materials exposed to harsh conditions. Advancements in solvent technology continue to open new possibilities for durability. Choosing the right solvent solution can significantly impact durability and reliability, ensuring success in even the most challenging applications.

Published by: Holy Minoza