Image commercially licensed from Unsplash

With a sharp focus on sustainable and planet-friendly service, today’s oxidation services are often informed by years of environmental engineering experience. This is undoubtedly the case with Oxidizers, Inc., which brings over 250 years of industry experience to the table.

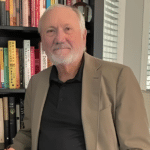

Oxidizers, Inc. is setting the pace for the more environmentally-focused manufacturing sector with a range of services in the oxidation and mechanical support realm. The company’s president, Keith Lambert, knew his experience and know-how could radically influence the environmental engineering market.

“I’ve seen companies start with good intentions, but the heart of the business can get lost if you’re not always intentional and purposeful,” Lambert explains. “I got into the environmental industry because I truly believe we are to be mindful of the planet, as it’s made for us and we’re made of it. It’s our duty to take care of it.”

Lambert has over 30 years of experience in the industry himself and knew what he wanted Oxidizers, Inc. to be from the outset. Over the years, he has seen the business grow and evolve beyond anything he imagined for the company.

What do oxidizers do?

The purpose of the service Oxidizers, Inc. provides may not be readily known to people outside the environmental engineering space. Many manufacturing plants cause harmful emissions, and oxidizers are employed to treat waste gas and emissions.

These oxidizers thermally rescue the waste emissions into simpler compounds that are not harmful to the planet — such as water vapor. Under the Clean Air Act, the EPA sets guidelines for releasing harmful emissions, making the work Oxidizers, Inc. does critical to the continued safe manufacturing process in various segments.

A continuously evolving service

Lambert considers himself fortunate that he has grown Oxidizers, Inc. beyond what he ever believed was possible. “Oxidizers has been fortunate enough to penetrate into just about every manufacturing segment in the US,” Lambert says. “When my partner and I started off, the goal was to be in the service and maintenance arena, then slowly migrate into supplying new equipment as well.”

Not only have Lambert and his team been able to add new equipment supply to their list of services and products, but also process support and studies, ceramic media replacement, upgrades, assessments, sheet metal fabrication, and general labor support. Lambert has grown Oxidizers, Inc. into a full-service supply and support source for the manufacturing industry.

As the company has grown, Lambert has tackled some of the most common issues with environmental engineering in the manufacturing sector. “This may sound strange, but the toughest challenge is typically overcoming production demand,” he explains. “It’s a vicious circle. Without production, no one works, and without proper maintenance, equipment breaks down. If you’re running a facility 24/7, it can be tough to justify and initiate downtime for routine maintenance and service.”

With years of experience informing the process support he gives to his clients, Lambert and his team have been able to walk clients through downtime, routine maintenance needs, and new equipment installs without too much damaging disruption to their production.

“Our team often gets called in when a company has a culture focused on production — and this can be a tough spot to be in,” says Lambert. “I’ve seen the desperation, stress, and concern when a maintenance manager wants to change the culture, but can’t because production is king. Over time, non-stop production erodes performance, which is tied to emissions results. You can’t pass an emissions test without proper maintenance and care.”

Technology advancements

Oxidizers, Inc. is also at the forefront of digital transformations and Industry 4.0 revolutions. By leveraging InCheq — another one of Lambert’s businesses — Oxidizers, Inc. has offered clients automated maintenance evaluations to streamline the maintenance process. They also offer cloud-based task verification and IIoT (Industrial Internet of Things), leading the pack in industrial technology services.

While oxidation services have been in play for decades, the injection of technology into the field is something new. “The next big push in my mind is to have intuitive tools that empower the end user. By taking advantage of IIoT or Industry 4.0 technologies, we now have greater equipment awareness so we can be more proactive with maintenance and efficiency,” says Lambert. With this new technology, manufacturing companies will no longer have to worry about surprise emission test failures, as they can continuously monitor their emissions on a daily basis. With the Clean Air Act as a guide for companies to stay compliant, this ability to keep on top of individual emission output is a game-changer.

The future for Oxidizers, Inc. includes more tech and more growth. “Our vision for Oxidizers is to continue expanding on the systems under our care, which I estimate to be in the trillions of cubic feet per year,” says Lambert. The team also hopes to bring more and more manufacturing companies into the Industry 4.0 world with their advanced digital resources. To Lambert and the team at Oxidizers, Inc., knowing where your equipment lies regarding maintenance needs and emissions is vital to a well-run, environmentally friendly industry across the board.