From conventional systems, manufacturing has moved to highly avant-garde and automated methods, making the process efficient, practical, and scalable in the last couple of decades. Special industrial equipment and machinery contribute immensely to any firm working in today’s highly competitive environment, driven by technology where quality standards are vital for sustaining competition with considerable efficiency concerning productivity. The following paper outlines today’s manufacturing processes’ essential tools and machinery. It covers the key hardware and information technologies modern businesses can use to meet demands in the contemporary, challenging market.

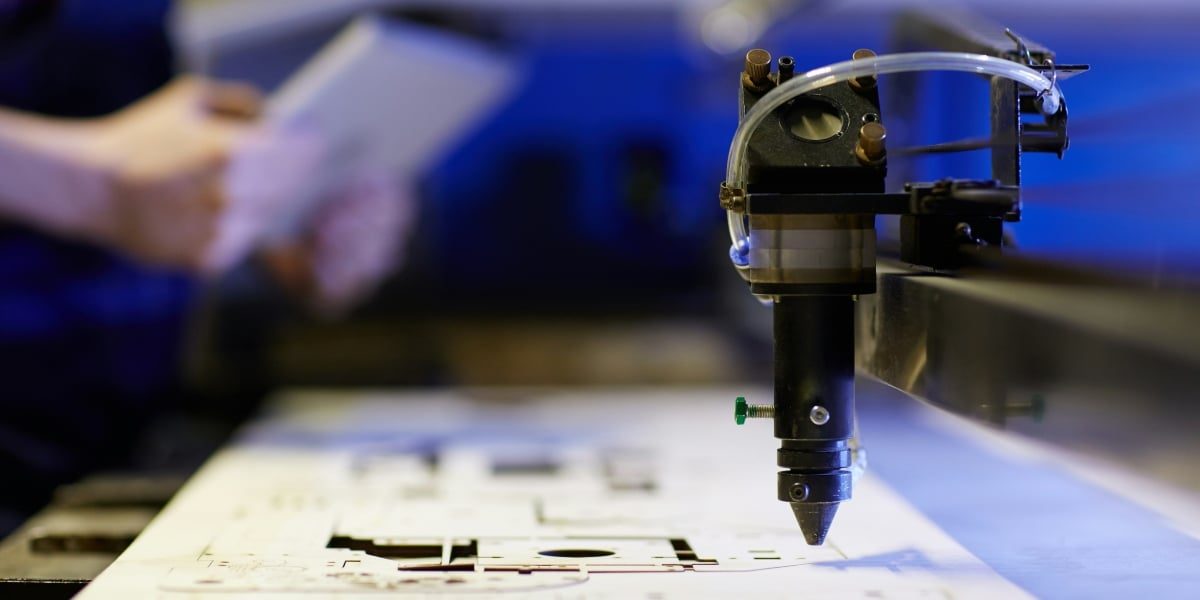

CNC Machines (Computer Numerical Control Machines)

Computer Numerical Control machines have helped revamp the manufacturing process through their capacity for high precision and automation in production. The machines operate via computer programming that dictates how tools move, allowing industrial equipment manufacturers to produce complicated parts with fantastic accuracy and incredible speeds. CNC machines come in varied forms, including mills, lathes, and routers, each for different manufacturing tasks.

- Benefits: Precision, repeatability, and the ability to handle complex designs.

- Applications: Used in industries such as automotive, aerospace, and electronics to produce parts like engine components, circuit boards, and machine tools.

Pumps

Pumps are essential to many manufacturing processes, essentially circulating fluids, gases, or slurries within the systems. They become imperative in cases where liquids and gases have to be moved for various applications such as cooling systems, lubrication circuits, chemical processing, and water treatment. Pack pumps come in different types and sizes and give flexibility and efficiency to suit specific needs in various manufacturing operations.

- Benefits: Pump action in transferring fluids and gases highly minimizes energy expenditure and is thus cost-effective in maintaining smooth production.

- Applications: Pumps are extensively used in industries related to chemical processing, automotive, food and beverage, pharmaceuticals, and oil and gas.

Electric Motors

The electric motor is the backbone of power machinery and equipment in today’s manufacturing process. They convert electrical energy into mechanical motion that drives many different types of manufacturing, from simple assembly lines to highly complex machinery. Many types exist to meet specific applications for manufacturers in the right solution to meet their production needs.

- Benefits: Electric motors are energy-efficient, reducing operational costs and minimizing environmental impact.

- Applications: Electric motors are widely used across industries, including automotive, robotics, consumer electronics, and industrial automation. In manufacturing, they power essential equipment such as conveyor belts, robotic arms, pumps, fans, and CNC machines.

Injection Molding Machines

Injection molding is one of the prevalent processes used to manufacture plastic parts in large volumes these days. It melts down plastic pellets with injection molding machines and, at high pressures, injects these into molds for a wide array of shapes. This methodology will be perfectly fitted to make large parts with complicated geometries; hence, it finds broad application in automotive, electronic, and consumer goods manufacturing.

- Benefits: High-volume production, low per-unit cost, and versatility in material choices.

- Applications: Manufacturing plastic parts for consumer electronics, automotive components, and packaging.

Gear Reducers

The gear reducers in modern times work to alter the speed and torque output of the motors involved in manufacturing. Known to be mechanical devices and mostly referred to as gearboxes or gear reducers, the gearboxes step down the input power at reduced speeds and increase torque so that machines and systems will perform the work efficiently. Therefore, in those applications where the question of precision and power transmission arises, gear reducers’ contribution becomes indispensable in manufacturing processes.

- Benefits: Gear reducers enhance efficiency by optimizing motor performance, increasing torque, and reducing the load on the motor.

- Applications: In manufacturing, they are essential for driving conveyors, crushers, mixers, and other heavy-duty machinery.

Milling Machines

The milling machine is one of the standard tools in today’s manufacturing for cutting, drilling, and shaping metals and other solid materials. Milling machines are fitted with rotating cutters around a workpiece to make complex, detailed parts. With improved CNC technology, this machine has a high degree of automation and makes exact, complex parts.

- Benefits: High precision and versatility in producing a wide range of parts.

- Applications: Used in industries such as automotive, aerospace, medical devices, and heavy machinery.

Industrial Lathes

A lathe is a machine type used to modify wood, metals, and plastic by turning a workpiece against different cutting tools. Most modern CNC lathes have very high precision and control, hence their ability to manufacture complicated geometries with close tolerances in parts. These machines are paramount in making cylindrical parts such as shafts, rods, and gears.

- Benefits: Precision in shaping parts with rotational symmetry.

- Applications: Automotive, aerospace, and machinery manufacturing, especially for creating shafts, bearings, and other cylindrical components.

Packaging Machines

Accordingly, efficient packaging is integral to manufacturing, ensuring the product is safely and attractively ready for distribution. Examples of packaging machines include bottling, labeling machines, sealing machines, and bagging machines- all of which have made the process easier. With automation, however, manufacturers can pack products faster and more consistently, with much less human error.

- Benefits: Increased speed, consistency, and reduced labor costs.

- Applications: Food and beverage, pharmaceuticals, and consumer goods industries.

Quality Control and Inspection Equipment

Quality has become an integral part of contemporary manufacturing machines to satisfy a customer’s demands and reach or even surpass the stipulated rules and regulations governing a given industry. Advanced quality control and inspection machines using CMM, optical scanners, and vision inspection systems will point out a part or product’s flaws or defects. The machine ensures that the products coming out will fall within the specifications set by the clients, reducing the defects in production.

- Benefits: High-accuracy inspection, consistency, and reduced defects.

- Applications: Used in industries such as aerospace, automotive, electronics, and medical device manufacturing.

Conveyor Systems

Conveyors from the premier industrial equipment suppliers are essential mechanisms to efficiently process material handling, product assembling, and goods transportation during a product’s cycle of manufacture. Many of these systems are automated, which moves the products from workstation to workstation, improving efficiencies and reducing the need for manpower. Modern manufacturing systems greatly rely on conveyor belts, rollers, and AGVs.

- Benefits: Increased efficiency, reduced labor costs, and improved workflow.

- Applications: Automotive assembly lines, warehouse logistics, and food production.

Bottom Line

Modern manufacturing involves high-end machinery for better productivity, precision, and efficiency. Everything has completely changed from CNC machines to robotic arms regarding designing, creating, and delivering a product. Manufacturers would incorporate inventions of such technologies to respond to ever-increasing global market demands, strive for quality in their products, and thereby be more competitive. The contribution of these machines will only continue to rise with the evolving manufacturing scenario in supporting the industry’s innovation, sustainability, and profitability.

Published by Mark V.