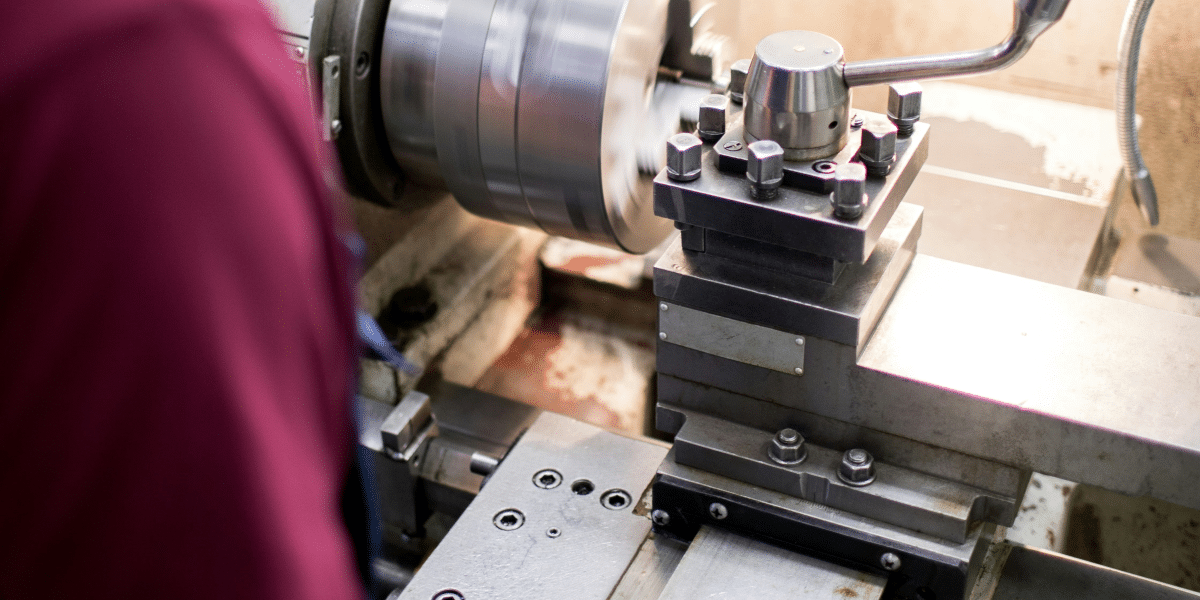

What Are CNC Industrial Cutting Machines?

CNC industrial cutting machines are essential tools in modern manufacturing, designed to precisely cut and shape materials using computer-controlled commands. These machines include laser, plasma, and water-jet cutters, each offering unique benefits for different applications. By automating the cutting process, CNC machines help increase efficiency and accuracy, reducing the chance of human error. Whether you’re working with metal, wood, or composites, these machines provide consistent and high-quality results, making them invaluable for industries like automotive, aerospace, and electronics. In essence, CNC industrial cutting machines help streamline production and enhance the quality of the final products.

How Do CNC Laser Cutters Work?

CNC laser cutters use a focused, high-energy laser beam for precise cutting or engraving of materials. The process starts with computer numerical control (CNC) technology, which guides the laser head according to pre-programmed designs. This non-contact, thermal-based method melts or vaporizes the material, allowing for intricate patterns and clean edges.

The cutter’s laser is typically generated from CO2, fiber, or crystal sources, each suited for different materials and thicknesses. As the laser moves, it traces precise paths, optimizing material usage and limiting the need for additional tools. This efficiency is particularly advantageous when working with metals, plastics, and even wood, providing versatility across multiple industries. The technology delivers a fast and efficient cutting process, which boosts production capabilities while ensuring consistent, high-quality results

What Are the Types of CNC Cutting Machines?

When exploring CNC industrial cutting machines, you’ll find several types suited to different tasks. CNC laser cutters are popular for their precision and ability to handle intricate designs using a focused laser beam. They’re ideal for materials like metal, plastic, and wood.

Then, there are CNC plasma cutters, which are great for cutting thicker metals efficiently. They use a high-powered plasma torch, making them faster than traditional methods. Water-jet cutters are another option known for their versatility; they can cut various materials without heat, preserving the integrity of the workpiece.

Each type of machine offers unique advantages, so your choice will depend on your project’s specific needs. Whether you need speed, precision, or versatility, CNC cutting machines provide a solution tailored to your requirements.

What Are the Advantages of Using CNC Machines?

CNC machines offer several benefits that enhance manufacturing processes. First, they provide high precision and accuracy, ensuring consistent quality in every piece. This reduces errors and material waste. Additionally, CNC machines are highly efficient, allowing for faster production times and increased throughput. They also require less manual intervention, which minimizes labor costs and improves safety. Furthermore, their flexibility lets you switch between tasks easily, adapting to different production needs. CNC machines boost productivity and cost-effectiveness, making them a valuable asset in modern industrial settings.

How Do CNC Machines Impact Different Industries?

CNC machines revolutionize various industries by enhancing precision and efficiency. In the automotive sector, they enable the production of intricate parts with minimal error, boosting overall quality. Aerospace companies use CNC machines to handle complex geometries and materials, ensuring safety and performance. In electronics, CNC technology facilitates the creation of detailed components critical for device functionality. These machines also streamline manufacturing processes, reducing costs and waste across sectors. By adopting CNC technology, industries can meet higher standards and improve competitiveness in a rapidly evolving market.

In summary, CNC industrial cutting machines are essential tools that enhance precision and efficiency across various industries. By understanding their types and benefits, you can leverage these machines to improve your manufacturing processes, ultimately leading to better productivity and competitive advantage in the market.

Published by: Khy Talara