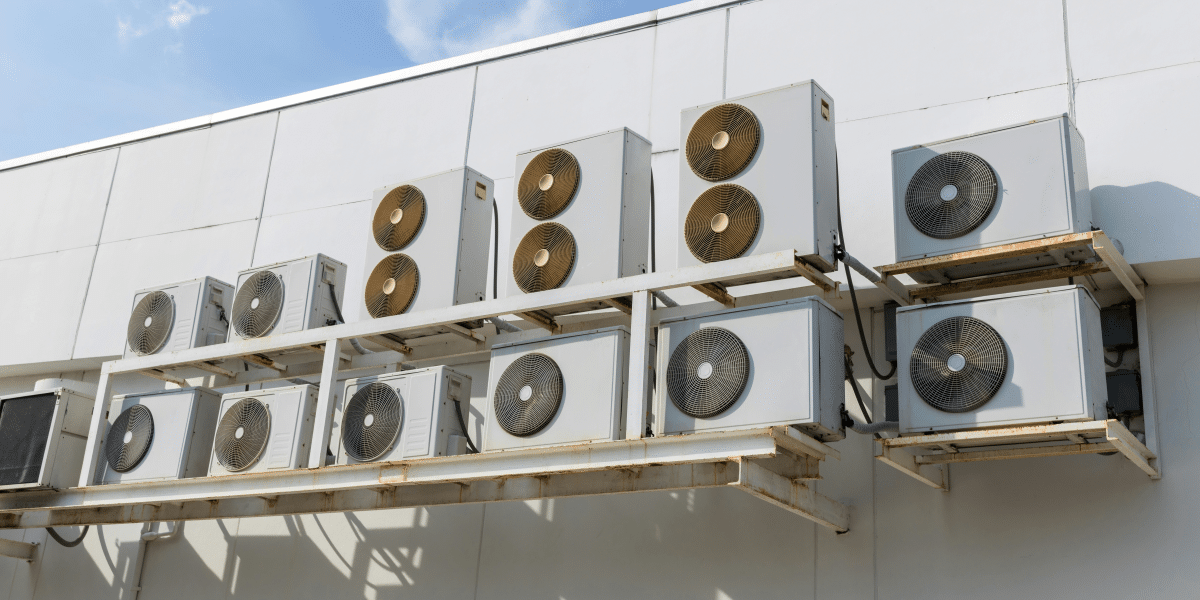

The HVAC (Heating, Ventilation, and Air Conditioning) industry is critical for ensuring comfort in residential, commercial, and industrial buildings. With growing environmental concerns and increased demand for energy efficiency, HVAC systems must not only provide comfort but also adhere to strict energy efficiency standards. Industrial automation plays a pivotal role in the HVAC manufacturing process, enhancing precision, efficiency, and product reliability. Among the technologies driving this automation, servo controllers stand out for their ability to improve the accuracy and speed of manufacturing processes. This article explores how industrial automation, specifically through servo controllers, is transforming HVAC manufacturing.

The Importance of Automation in HVAC Manufacturing

HVAC systems encompass a wide range of products including air conditioners, furnaces, heat pumps, and ventilation units, each requiring the assembly of numerous components like compressors, heat exchangers, and ductwork. The precision in manufacturing these components directly affects the efficiency, performance, and durability of the HVAC systems. Industrial automation helps address these challenges by:

Enhancing Production Precision and Consistency

Automated manufacturing systems ensure that each component is produced with high precision and uniformity, minimizing variability that can affect the performance of the HVAC system.

Increasing Production Efficiency

Automation allows for continuous production with minimal downtime, significantly increasing the output and meeting market demands more effectively.

Reducing Manufacturing Costs

By automating repetitive and labor-intensive tasks, manufacturers can reduce labor costs and minimize human error, which in turn decreases waste and increases yield.

Improving Product Quality

Automated systems provide consistent quality control throughout the manufacturing process, ensuring that every product meets stringent industry standards.

Applications of Industrial Automation in HVAC Manufacturing

Component Fabrication

Many components of HVAC systems, such as metal ducts or plastic vents, require precise fabrication to ensure proper fit and function. Servo controllers are extensively used in the machinery that cuts, molds, and assembles these parts, offering exact control over the speed and movement of the tools, which is crucial for maintaining tight tolerances and ensuring high-quality finishes.

Assembly Lines

Automated assembly lines use robots and other automated machinery to assemble various components of HVAC units. Servo controllers play a critical role here, managing the complex movements required to assemble delicate parts such as electrical circuits or piping connections accurately.

Testing and Quality Control

HVAC units must undergo rigorous testing to ensure they meet performance and safety standards. Automation technologies are used to simulate various operating environments and load conditions, with servo controllers precisely regulating the testing equipment to apply the correct pressures, temperatures, and electrical loads.

Packaging and Shipping

The final step in the manufacturing process involves packaging the units for shipping. Automated packaging systems, guided by servo controllers, ensure that each unit is securely packed to prevent damage during transportation, optimizing the use of packaging materials and reducing waste.

The Role of Servo Controllers in HVAC Manufacturing Automation

Servo controllers are integral to enhancing the functionality and reliability of automated systems in HVAC manufacturing. These devices precisely control the motion of servo motors that drive the majority of the automated machinery used in the industry. The ability of servo controllers to adjust motor speed, position, and torque in real-time is particularly beneficial for tasks requiring high precision, such as the intricate assembly of electronic components or the precise cutting of metal parts.

- Precision Control: Servo controllers (DKC02.3-200-7-FW/S10 for example) provide the fine control needed for processes where exact movement and placement are crucial to product quality.

- Flexibility: These controllers allow for quick reprogramming of robotic systems to handle different tasks or adapt to new product designs, making it easier for manufacturers to introduce new models or customize products.

- Efficiency: By optimizing the movement of machinery, servo controllers reduce cycle times and energy consumption, contributing to a more efficient production process.

Challenges in Automating HVAC Manufacturing

Despite the benefits, automating HVAC manufacturing presents several challenges:

High Initial Investment

- The cost of implementing high-precision automation equipment, including sophisticated servo controllers and related technologies, can be significant.

Technical Complexity

- Developing and maintaining advanced automated systems requires a high level of technical expertise. Manufacturers must invest in skilled personnel to manage these systems effectively.

Integration with Legacy Systems

- Many HVAC manufacturers operate with legacy systems that may not be easily compatible with modern automation solutions, requiring significant modifications or customized solutions.

Future Outlook

As technology continues to advance, the role of automation in HVAC manufacturing is expected to grow. Emerging technologies like artificial intelligence and the Internet of Things (IoT) are likely to further enhance the capabilities of automated systems, enabling smarter, more adaptive manufacturing processes that can anticipate and correct production anomalies in real time.

Conclusion

Industrial automation, particularly through the use of advanced servo controllers, is playing a transformative role in the HVAC manufacturing industry. By enhancing precision, efficiency, and quality, automation helps manufacturers meet the challenges of modern HVAC demands. As the industry continues to evolve, embracing these advanced technologies will be crucial for staying competitive in a market that increasingly values energy efficiency and high performance.

Published by: Holy Minoza