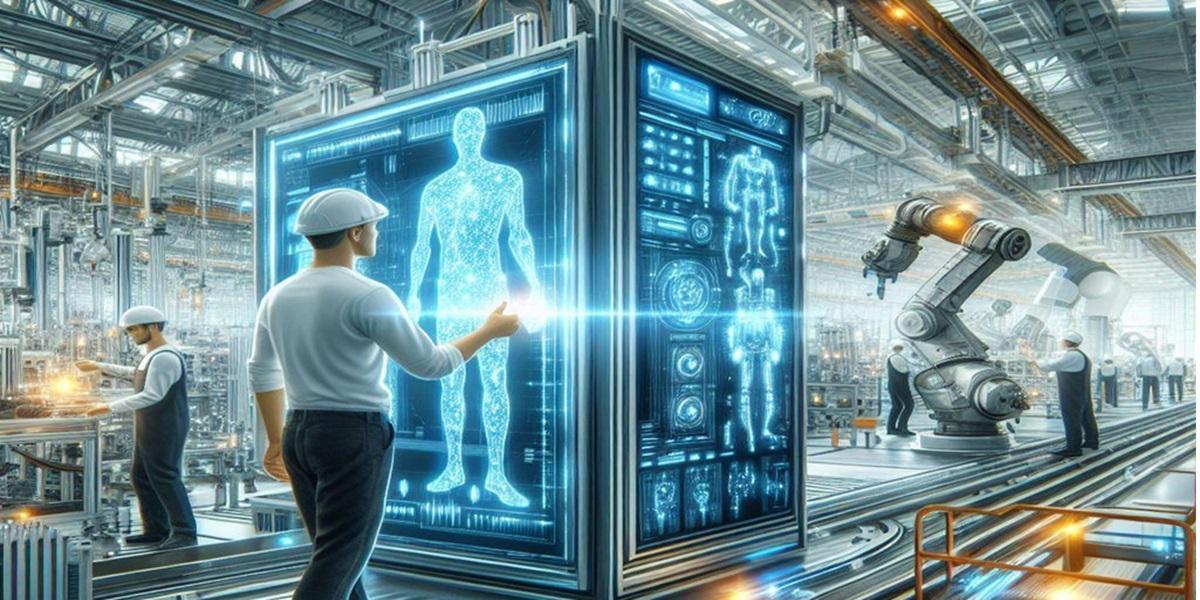

Within the dynamic landscape of modern manufacturing, a silent but seismic shift is occurring—a revolution fueled by the relentless advancement of machine learning. Envision a world where machines anticipate their own maintenance requirements, automotive behemoths meticulously identify imperfections, and retail juggernauts forecast consumer demand with unprecedented precision. Welcome to the forefront of innovation in manufacturing, where the future isn’t just envisioned; it’s being meticulously crafted through the transformative power of machine learning.

Companies such as General Electric Aviation are utilizing machine learning (ML) techniques to analyze real-time sensor data and anticipate equipment failures in advance. By recognizing subtle patterns that may indicate possible problems, these systems enable manufacturers to be proactive, improving operational reliability and prolonging the lifespan of assets. Proactive equipment management, in which issues are handled before they become major, is promoted by predictive maintenance, which also helps to avoid expensive downtime. In addition to reducing costs, this predictive strategy improves worker safety by avoiding unanticipated equipment breakdowns. These sophisticated systems are anticipated to become more accurate and dependable as machine learning (ML) methods undergo further evolution and improvement, leading to even greater optimization of manufacturing operations. Companies may enhance their bottom line by reducing maintenance costs, allocating resources more efficiently, and foreseeing equipment failures with unparalleled accuracy.

Quality Control Revolutionized

Using machine learning (ML) to aid computer vision systems, automotive manufacturers like BMW are raising the standard for quality control among their products. These systems, powered by machine learning algorithms, check manufactured components with an accuracy and speed unmatched by any other system. They are able to detect even the slightest faults, such as scratches, dents, or misalignments, automatically. By ensuring that only faultless products are brought to market, these technologies safeguard the reputations of brands and ensure that customers continue to get what they want. In addition to detecting defects, ML-assisted quality control systems can provide valuable insights for process improvement. By analyzing data collected during inspections, manufacturers can identify recurring issues and implement corrective actions to prevent future defects. This continuous feedback loop enables companies to refine their manufacturing processes and drive ongoing quality improvements.

Supply Chain Mastery

Retail giants like Amazon are transforming inventory management and forecasting demand using advanced ML models. These systems accurately predict consumer demand at specific locations and times by analyzing vast datasets consisting of historical sales figures, market trends, and external factors. Precise inventory planning and logistics management enabled by ML result in reduced stockouts minimized excess inventory, and optimized overall supply chain efficiency. These supply chain management systems, backed by machine learning, can predict demand and simultaneously optimize inventory levels and distribution networks in real time. Companies can optimize their inventory management by constantly altering inventory levels in response to demand projections and lead times. This approach allows them to minimize the expenses associated with carrying inventory while guaranteeing that products are readily available to customers at the right time and place. This agile supply chain management methodology improves customer satisfaction and promotes long-term loyalty.

Machine Learning’s Role in Energy Efficiency

Companies in several industries, from steel production to consumer electronics manufacture, are adopting machine learning algorithms to manage energy usage and reduce environmental impact efficiently. Tesla’s Gigafactories epitomize this pattern, employing machine learning algorithms to optimize requiring energy procedures like battery manufacturing. Implementing waste reduction and efficiency optimization strategies throughout the manufacturing process guarantees a more environmentally sustainable future.

Fine-Tuning for Peak Performance

Intel and other semiconductor makers utilize machine learning-driven analytics to improve their production processes and increase their yields. Continuous monitoring of sensor data and production metrics allows for the identification of inefficiencies and anomalies, which in turn provides engineers with valuable insights that can be used to implement targeted optimizations. Enhancements follow these improvements in product quality, throughput, and resource conservation.

Staying Ahead of the Curve

Companies that focus on fast-moving consumer goods (FMCG), such as Procter & Gamble, utilize machine learning to anticipate changes in consumer preferences and market demands. A sophisticated machine learning model examines data from social media trends, online sales channels, and historical purchasing habits to generate ideas that may be put into action. The ability to respond quickly and effectively to opportunities in emerging markets results in more significant revenue and sustainable growth.

With machine learning acting as the driving force, the future looks promising.

There is no denying the impact that machine learning has had on the manufacturing industry. It has been the driving force behind breakthroughs in areas such as demand forecasting, supply chain optimization, energy efficiency, predictive maintenance, and quality control, respectively. The potential for continual improvement and innovation is virtually limitless as long as businesses continue to allocate resources to machine learning-driven technology and cultivate cultures that are data-centric. By utilizing machine learning to react to ever-changing market conditions, manufacturers are able to maintain their competitive edge, embrace sustainability, and surpass the expectations of their customers.

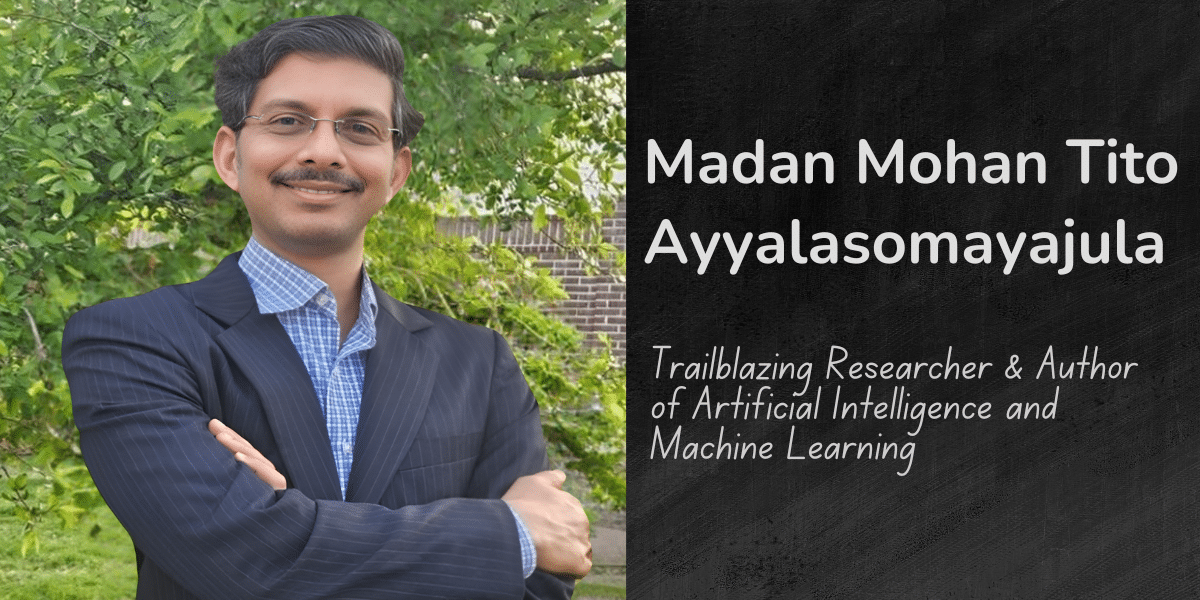

About the Author: Madan Mohan Tito Ayyalasomayajula

Madan Mohan Tito is a distinguished senior technology architect currently working in the manufacturing domain and has garnered an illustrious career that spans over two decades. With a rich background in cutting-edge technologies, his AI and machine learning expertise has been pivotal in propelling growth, elevating user experiences, and implementing advanced and innovative methodologies. In addition to his professional endeavors, Mr. Madan generously dedicates his time to mentoring and refereeing in the tech community. His steadfast commitment to nurturing the next generation of tech professionals through mentorship and identifying opportunities for their advancement is widely acknowledged and appreciated. Furthermore, Mr. Madan is pursuing his doctoral degree in computer science, concurrently contributing as a researcher and author. His dedication to scholarly pursuits underscores his passion for pushing the boundaries of knowledge and innovation in technology.

Published by: Khy Talara