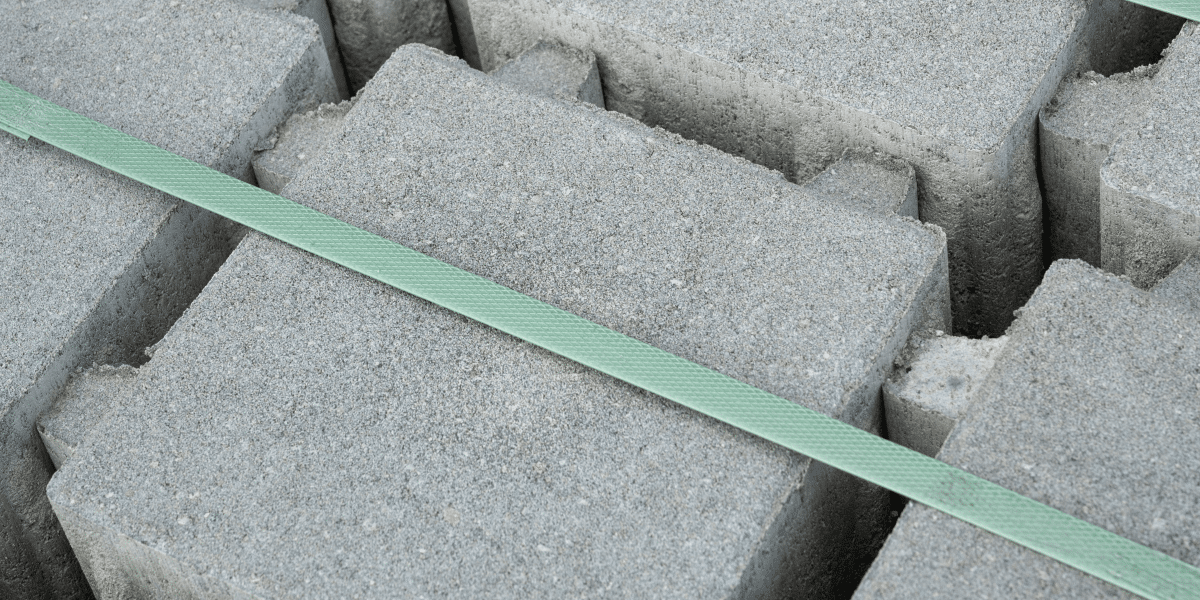

Modern infrastructure depends on new building materials and methods. This aims to improve efficiency, safety, and durability. One exciting development is precast concrete light pole bases. These bases are made in a factory. Then, this is brought to the construction site. This makes the building process faster.

They are stronger and more reliable than traditional methods where concrete is poured on-site. Precast bases also help reduce mistakes and save money. Their consistent quality and easy installation make them a smart choice for builders. Here are the key advantages of using precast concrete, light pole bases in modern construction projects.

Enhanced Durability

Precast concrete light pole base details are made in controlled conditions to ensure consistent quality and strength. This makes them very durable and resistant to weather, corrosion, and chemicals. Because of this, they can:

- handle harsh conditions

- last a long time

- lower maintenance costs

Time Efficiency

Using precast concrete light pole bases greatly speed up installation time compared to traditional methods. They are made off-site, so there’s no waiting for on-site curing, which can take several days.

This faster method helps projects finish quicker and reduces disruptions to the area. Quicker installation means that projects can stay on schedule and within budget.

Cost-Effectiveness

Although the initial costs of precast concrete components may be higher than on-site cast alternatives, they become more cost-effective over time. Shorter installation times and lower labor costs. There is less need for maintenance, which leads to big savings.

Also, the consistent quality and reliability of precast elements can prevent expensive repairs and replacements in the future.

Superior Quality Control

Precast concrete light post products are made in a factory where quality is carefully checked. This makes sure each light pole base meets certain structural and design standards. Because precast concrete is consistent, engineers and developers can trust that each unit will work the same. This improves the safety and strength of the infrastructure.

Design Flexibility

Precast concrete light pole bases are flexible in design, fitting different looks and needs. Makers can create bases in various:

- shapes

- sizes

- finishes

These help to suit specific projects. This flexibility helps architects and engineers design urban areas and infrastructure. This can be strong and look good too.

Environmental Benefits

Producing precast concrete is often better for the environment than traditional construction methods. Factory production allows for precise material measurements and reduces waste. Also, using recycled materials and lowering the environmental impact on-site match up with sustainable practices.

By choosing precast concrete, developers help create greener buildings and save resources.

Invest in the Advantages of Precast Concrete Light Pole Bases

In conclusion, using precast concrete light pole bases brings great advantages to modern construction. They are durable, save time, reduce costs, and provide high-quality control. They offer design flexibility and environmental benefits. These features make them a smart choice for different infrastructure projects.

As cities grow and change, this will help create safer and more sustainable urban areas. This approach will play a key role in building cities. Because of this, they can adapt to future needs. So, don’t wait! Help ensure the well-being of their residents today!

Published by: Martin De Juan