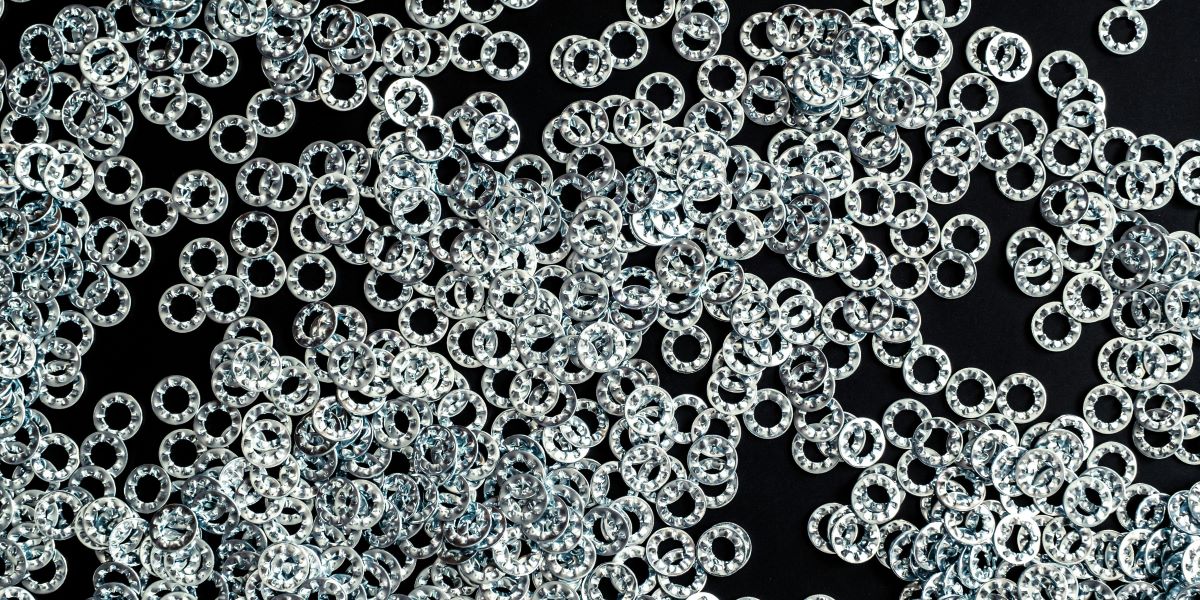

Fastening mechanisms are essential, with set screws being particularly noteworthy for their practicality and effectiveness. This detailed guide delves into the importance of screws in fastening applications while highlighting their uses, benefits, and distinguishing features.

What Exactly are Set Screws?

Tiny yet powerful, set screws are threaded fasteners used to firmly attach one object to another, either inside or against it—usually without heads—so they sit flush with or below the surface for a smooth appearance. Their snug fit into tapped holes allows for a secure hold without sticking out noticeably. Their inconspicuous nature makes them perfect for situations where both looks and performance are essential.

The Practical Uses of Set Screws

Set screws are commonly employed in a range of industries, such as engineering, electrical installations, and plumbing systems, for various purposes like securing components in place and preventing any undesired shifts or movements in machinery or sensitive equipment, such as electronic devices and piping systems.

Varieties

Set screws are available in various materials, including steel, brass, and alloy steel, to suit different project or task requirements. Each material offers unique properties, such as corrosion resistance or increased strength. Additionally, various styles—such as cup point, flat point, and cone point—provide versatility, with each design addressing specific mechanical needs.

Benefits of Utilizing Set Screws

Set screws offer numerous advantages that make them essential for fastening tasks. They are small and perfect for use in confined areas where other fasteners may be too bulky. Moreover, set screws offer a hold without requiring components like nuts or washers. This straightforward approach saves time during installation and cuts down on maintenance needs.

Installation Techniques

For optimal results with set screw installation, first, pick the size and type that suits the job at hand. Ideal for the threaded hole to be clean and fits the screw properly. When putting them in place, be consistent with pressure to prevent harm to the parts involved. A torque wrench will help get the tension right and improve how well the fastener holds things together.

Addressing Everyday Problems

While set screws are known for their dependable, reliable nature, issues may arise with them at times. One common issue is loosening caused by vibration or incorrect installation. To tackle this problem, it is advisable to use thread-locking compounds, as they improve grip and prevent loosening. In situations where the screw gets stripped, replacing it with a new one will help maintain performance. Regular checkups and upkeep also play a role in averting any difficulties.

Choosing the Correct Set Screw

When selecting the right set screw for your needs, you’ll need to take into account several factors. Consider the requirements of your application, including how much weight it will bear and the environmental factors involved. The choice of material is crucial for longevity, while the type of screw influences its ability to grip securely. Seek advice from professionals and refer to industry guidelines to help you decide.

The Evolution of Set Screw Innovations

Technological progress plays a role in shaping the design and performance of screws over time. New materials with enhanced durability and resistance to corrosion are expanding the range of uses for these fasteners. Additionally, advancements in production methods are improving accuracy and dependability. These enhancements help set screws remain a reliable option for securing components and adapting to the evolving needs of industries.

Summary

Set screws play a crucial role in fastening due to their compact design and wide range of uses. They are preferred in industries for their ability to securely hold objects without sacrificing appearance. Knowing the advantages of screws, along with how to install them and address any possible problems, is key to their practical use. As technology progresses, set screws will continue to evolve while remaining integral components in various applications.

Published by Iris S.