Choosing the right motor for your industrial application is a critical decision that directly impacts the efficiency, productivity, and longevity of your machinery. Motors are the heart of various industrial systems, driving equipment and machinery across manufacturing, processing, and automation sectors. The right motor can boost operational efficiency, reduce energy costs, and improve overall system performance. On the other hand, selecting an unsuitable motor can lead to frequent breakdowns, increased maintenance costs, and even premature equipment failure.

With numerous motor types, configurations, and specifications available, making an informed decision can be overwhelming. This guide aims to simplify the process by outlining the key factors you need to consider when choosing the right motor for your industrial application. Whether you’re purchasing from a trusted motor distributor or consulting with experts, understanding these fundamental aspects will help you make the wisest choice for your specific needs.

Understanding Motor Types

The first step in selecting the right motor is understanding the different types available and how they function. Each motor type has its advantages and is suited to specific industrial applications. Below are some of the most common types of motors used in industrial settings:

AC Motors (Alternating Current Motors)

AC motors are one of the most widely used motors in industrial applications. They are powered by alternating current and come in two primary types: synchronous and induction motors.

- Synchronous Motors: These motors operate at a constant speed, regardless of the load, as long as the power supply frequency remains constant. Synchronous motors are ideal for applications where precise speed control is required.

- Induction Motors: Also known as asynchronous motors, these are the most common type of AC motors. They are simple, rugged, and cost-effective, making them suitable for a wide range of industrial applications. Induction motors are widely used in pumps, conveyors, and compressors.

DC Motors (Direct Current Motors)

DC motors are powered by direct current and are known for their excellent speed control. They are often used in applications where varying speeds are necessary. DC motors can be further classified into:

- Brushed DC Motors: These motors use brushes to deliver current to the rotor. While they are inexpensive and easy to control, they require regular maintenance due to wear and tear on the brushes.

- Brushless DC Motors: These motors are more efficient and require less maintenance compared to brushed DC motors. They are often used in applications that require high reliability and long service life, such as robotics and industrial automation.

Servo Motors

Servo motors are precision motors that offer excellent control over position, speed, and torque. They are typically used in applications that require high accuracy, such as CNC machinery, robotics, and automated manufacturing systems.

Stepper Motors

Stepper motors are another type of precision motor used for controlling movements in small steps. These motors are commonly used in applications that require accurate positioning, such as 3D printers, automated medical equipment, and semiconductor manufacturing machines.

Factors to Consider When Choosing an Industrial Motor

Once you understand the different motor types, the next step is to evaluate the specific requirements of your industrial application. Several factors will determine which motor is suited to your needs.

Power and Torque Requirements

The power output of the motor, measured in horsepower (HP) or kilowatts (kW), is one of the most critical factors to consider. The motor must have sufficient power to drive the load and perform the required tasks efficiently. However, it’s not just about power; torque—the force that causes rotation—is equally important. Torque requirements can vary significantly depending on the application.

- Constant Torque Applications: If your application requires a constant amount of torque regardless of speed, such as conveyors or compressors, a motor that can maintain stable torque is essential.

- Variable Torque Applications: In applications such as fans or pumps, torque varies with speed. In these cases, selecting a motor with variable speed capabilities may improve efficiency.

Speed Control

Motor speed is another crucial consideration. Different industrial processes may require motors that operate at fixed or variable speeds. If precise speed control is essential for your application, such as in machining or processing equipment, motors like synchronous AC motors, DC motors, or servo motors are ideal. Variable frequency drives (VFDs) can also be used to control the speed of AC motors, offering more flexibility.

- Fixed Speed Motors: These are suitable for applications where a constant speed is required. Synchronous motors are a good example of fixed-speed motors.

- Variable Speed Motors: For applications that require varying speeds, such as in conveyor systems or pumps, DC motors or motors controlled by VFDs are preferable.

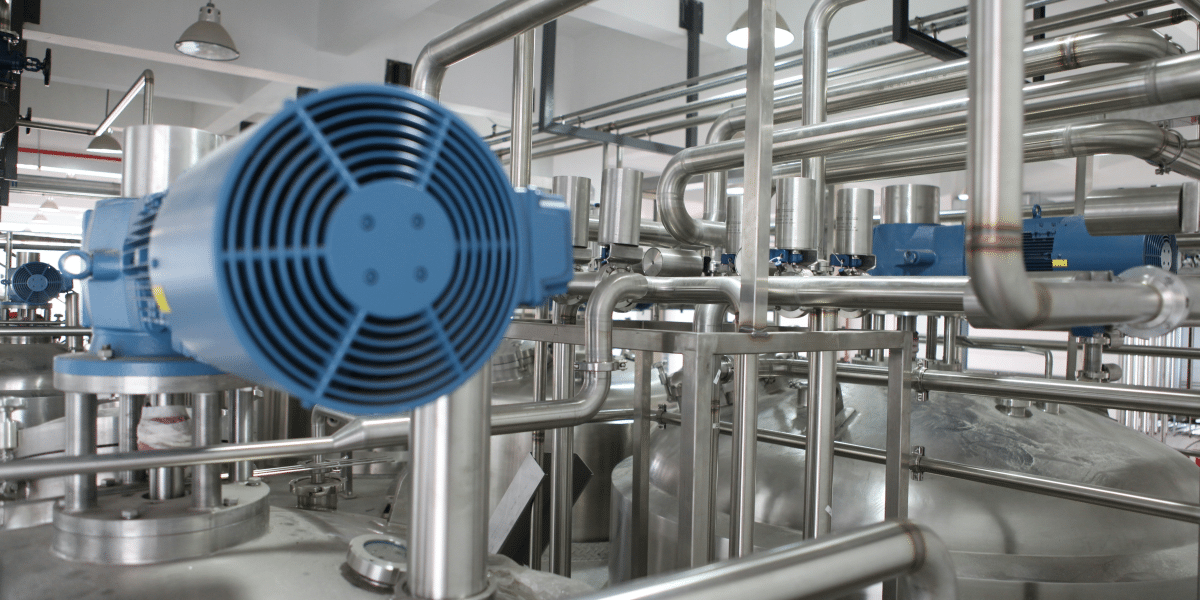

Operating Environment

The environment in which the motor will operate plays a significant role in determining the superior motor for your application. Industrial environments can vary widely, from clean and controlled settings to harsh and hazardous conditions. The motor you choose must be durable enough to withstand these environmental factors.

- Temperature: Motors operating in high-temperature environments may require special insulation or cooling mechanisms to prevent overheating.

- Dust and Debris: In dusty or dirty environments, motors should have adequate protection, such as totally enclosed fan-cooled (TEFC) enclosures, to prevent contaminants from entering the motor and causing damage.

- Humidity and Moisture: Motors used in wet or humid environments should be equipped with corrosion-resistant materials or sealed enclosures to prevent moisture from affecting the motor’s performance.

Efficiency and Energy Consumption

In today’s industrial landscape, energy efficiency is a priority. Choosing an energy-efficient motor can significantly reduce your operational costs and minimize environmental impact. Look for motors that comply with energy efficiency standards, such as IE3 or NEMA Premium efficiency ratings.

Motors with higher efficiency ratings may have a higher upfront cost, but the energy savings over the motor’s lifespan often make them a cost-effective choice in the long run. High-efficiency motors are particularly beneficial in applications where the motor will run for long periods, such as in HVAC systems or continuous production lines.

Motor Size and Mounting

The physical size of the motor and how it will be mounted are practical considerations that cannot be overlooked. Ensure that the motor you select fits within the available space in your machinery or equipment. Additionally, consider the mounting options, as different motors come with various mounting configurations, such as foot-mounted or flange-mounted designs.

If the motor needs to be easily accessible for maintenance, make sure that the chosen model allows for straightforward installation and servicing.

Starting Requirements

The way a motor starts can have a significant impact on your machinery and power systems. Some motors, especially larger ones, draw a significant amount of current when starting, which can strain the power supply. Understanding the starting requirements is essential for avoiding damage to your system.

- Direct-On-Line (DOL) Starting: This is the simplest starting method but can cause a large inrush of current. It’s typically used for smaller motors.

- Soft Starters: These reduce the starting current, providing a smoother start and minimizing wear and tear on the motor and connected equipment.

- VFD Starting: Variable Frequency Drives allow for controlled acceleration and deceleration, reducing mechanical stress on the motor and extending its lifespan.

Working with a Reliable Motor Distributor

Choosing the right motor for your industrial application can be a complex process, requiring careful consideration of several technical and operational factors. Working with a reputable motor distributor can simplify this process and ensure that you select the ideal motor for your specific needs.

A knowledgeable distributor can provide expert guidance, recommend the most suitable motor based on your application, and offer additional services such as installation, maintenance, and troubleshooting. They can also help you evaluate various motor brands and models, ensuring that you invest in a high-quality motor that meets your performance and budget requirements.

Conclusion

Selecting the right motor for your industrial application involves balancing a range of factors, from power and speed requirements to environmental conditions and energy efficiency. Whether you’re dealing with heavy machinery, conveyor systems, or precision equipment, the motor you choose must align with the specific demands of your application to ensure optimal performance and reliability.

Published by: Josh Tatunay