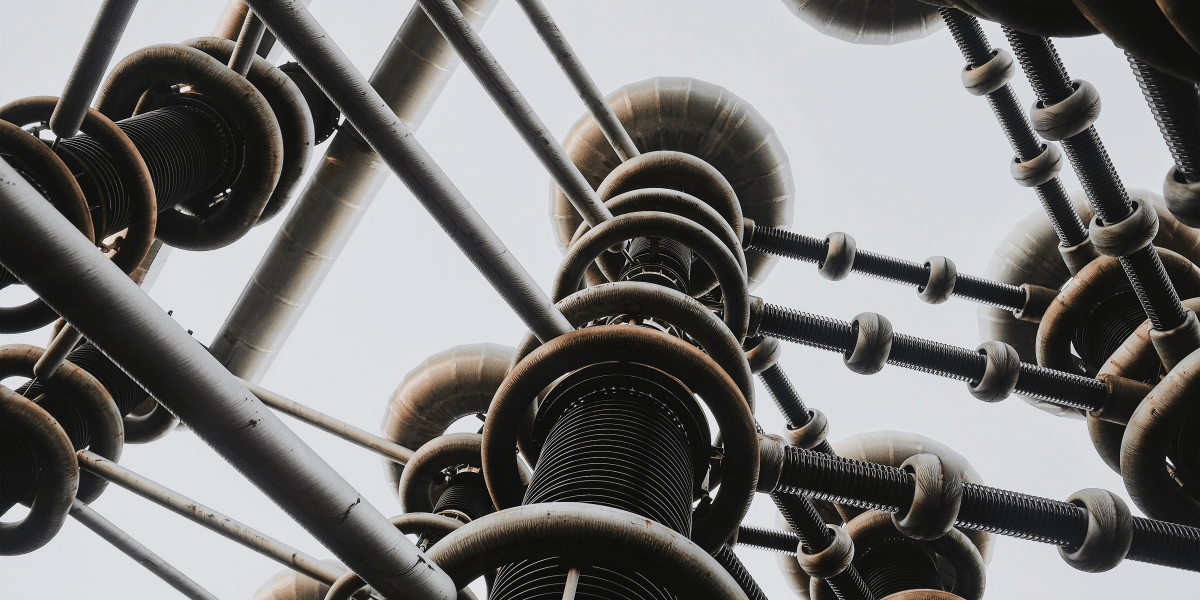

Choosing the right multi-spindle coil winder is crucial for manufacturers involved in coil winding processes. These machines are essential for producing coils in various industries, including electronics, telecommunications, medical devices, and automotive components. Selecting the right multi-spindle coil winder ensures efficiency, precision, and product quality, all essential to maintaining a competitive edge.

This article will explore the key factors to consider when choosing a multi-spindle coil winder, focusing on how these considerations impact your primary coil winding operations.

1. Number of Spindles

The first and perhaps most crucial factor is the number of spindles on the machine. Depending on the production requirements, multi-spindle coil winders come in various configurations, ranging from two to over ten spindles. The number of spindles determines how many coils can be wound simultaneously, directly affecting your production capacity.

If your production volume is high, opting for a multi-spindle winder with more spindles can significantly increase output. On the other hand, if you specialize in smaller production runs or prototype development, a machine with fewer spindles might be more appropriate, as it allows for more flexibility in settings and operations.

2. Precision and Tension Control

When it comes to primary coil winding, precision is everything. One of the most important considerations when selecting a multi-spindle coil winder is its ability to accurately maintain tight tolerances and control tension. This is particularly critical when dealing with fine wires used in applications such as transformers or motors, where even the slightest variance in coil winding can result in performance issues.

Look for machines that offer advanced tension control mechanisms, allowing for uniform wire tension throughout the winding process. Inconsistent tension can lead to too loose or tight coils, impacting the coil’s inductance, resistance, and overall efficiency. A machine that provides real-time tension feedback and adjustments is ideal for precision.

3. Customization and Flexibility

Different applications require different coil designs; not all coils are created equal. Therefore, the ability to customize winding parameters is a key factor to consider. Multi-spindle coil winders that offer flexible programming options can accommodate a range of coil specifications, such as wire gauge, winding speed, and turn count. This flexibility is essential for manufacturers who work with diverse coil designs or need to adapt quickly to changing customer demands.

Some machines allow you to save multiple winding profiles, which can be easily recalled when switching between jobs. This feature improves efficiency and reduces the risk of human error during setup, ensuring that each coil is wound to the exact specifications every time.

4. Automation and Operator Interface

Automation is crucial in improving productivity and reducing labor costs in modern manufacturing processes. When choosing a multi-spindle coil winder, it’s important to evaluate the machine’s level of automation. Highly automated machines can handle tasks such as wire feeding, cutting, and even bobbin loading, allowing operators to focus on quality control rather than manual tasks.

Equally important is the operator interface. Look for machines with user-friendly control panels that offer intuitive programming and monitoring. A clear and easy-to-use interface ensures operators can quickly adjust settings, monitor progress, and troubleshoot issues without extensive training.

5. Material Handling and Bobbin Size

Another key consideration is the size and type of bobbins the multi-spindle coil winder can handle. Depending on your primary coil winding operations, you may need to wind coils on various bobbin sizes. A machine that can accommodate various bobbin dimensions offers greater flexibility and allows you to cater to different customer requirements without needing to invest in multiple machines.

In addition to bobbin size, consider how the machine handles materials during the winding process. Automated material handling features, such as automatic bobbin loading and unloading, can potentially reduce downtime between production runs and enhance overall efficiency.

6. Machine Footprint and Space Requirements

The physical size of the multi-spindle coil winder is an important factor, especially if your production facility has limited space. A compact machine with a smaller footprint might be more suitable for smaller shops, while larger facilities with higher production volumes can accommodate larger, more robust machines.

When evaluating the machine’s footprint, also consider the layout of your production line. Ensure operators have enough space to work comfortably and safely around the machine. A well-planned layout can streamline the coil winding process and minimize the risk of accidents or production delays.

7. Durability and Maintenance

Investing in a multi-spindle coil winder is a long-term commitment, so durability and ease of maintenance should not be overlooked. High-quality machines made from durable materials will ensure your investment continues to perform reliably for years, even under heavy use.

Additionally, consider the ease of maintenance. Machines that offer easy access to routine cleaning and maintenance components can help minimize downtime and reduce the likelihood of costly repairs. Some manufacturers also offer remote diagnostic tools that allow quicker troubleshooting and support, which can be invaluable in maintaining productivity.

8. Speed and Efficiency

Speed is crucial in any production environment, and coil winding is no exception. The winding speed of a multi-spindle coil winder determines how quickly you can complete a production run. However, it’s important to find a balance between speed and precision. A machine that sacrifices precision for speed could lead to quality issues that negate the benefits of faster production.

Consider for a machine that offers adjustable winding speeds, allowing you to optimize the speed for different wire types and coil designs. Some advanced multi-spindle winders also feature real-time speed adjustments based on the wire tension and other factors, ensuring that both speed and precision are maintained throughout the process.

9. Cost and Potential Return on Investment

The cost of a multi-spindle coil winder can vary widely based on the number of spindles, features, and level of automation. When making your decision, it’s important to consider the initial investment and the potential long-term return on investment (ROI).

Calculate the potential cost savings in terms of increased production capacity, reduced labor costs, and improved product quality. While a high-end machine may require a larger upfront investment, its efficiency, precision, and reliability benefits may potentially provide ROI over time.

10. Technical Support and Service

Even the most reliable machines may require occasional technical support or service. Before making a purchase, research the manufacturer’s reputation for customer support. Ensure that they offer comprehensive service plans, including maintenance, repairs, and parts replacement. It’s also helpful if the manufacturer provides training for your staff, ensuring they can operate the machine efficiently and troubleshoot minor issues.

Some manufacturers offer remote support services, allowing technicians to diagnose and resolve issues without needing to visit your facility. This can be a major advantage, minimizing downtime and keeping your production line running smoothly.

11. Compliance with Industry Standards

Depending on your industry, there may be specific regulatory standards that your coil winding processes must meet. For example, manufacturers in the medical or aerospace industries often have stringent quality control requirements. Ensure that the multi-spindle coil winder you choose can produce coils that meet these standards.

Additionally, consider any certifications the machine may hold, such as ISO compliance or other industry-specific certifications. A machine that meets recognized standards can provide peace of mind and quality assurance.

12. Scalability and Future-Proofing

As your business grows, your production needs will likely increase. Choosing a multi-spindle coil winder that can scale with your operations is a wise investment. Look for machines offering modular designs or upgrade options, allowing you to add spindles or increase automation levels as needed.

Future-proofing your equipment ensures you won’t need to purchase an entirely new machine as your production capacity expands. Instead, you can make incremental upgrades that keep your operations efficient and competitive.

Conclusion

Choosing the right multi-spindle coil winder is a critical decision that impacts your primary coil winding operations’ efficiency, quality, and scalability. By considering factors such as the number of spindles, precision and tension control, automation, material handling, and potential long-term ROI, you can make an informed choice that aligns with your production needs and business goals.

Investing in the right machine improves production efficiency and enhances the quality of your coils, ensuring that your products meet high industry standards. With the right equipment in place, your coil winding operations will be positioned for success, whether you’re producing coils for transformers, medical devices, or any other application.

When selecting a multi-spindle coil winder, evaluate these factors thoroughly. Doing so will help you choose a machine that meets your immediate production needs while also allowing for future growth and expansion.

Published by: Annie P.