In the realm of electrical systems, the panel board is a central figure in the distribution and management of power. As the hub where electricity is divided and dispatched to various circuits, panel boards are indispensable for ensuring a steady and safe power supply to buildings and facilities. This article delves into panel boards’ essence, types, and significance in an electrical infrastructure.

Definition and Basics: An In-Depth Look at Panel Boards

Panel boards, commonly known as distribution boards, breaker panels, or electric panels, play a pivotal role in the infrastructure of modern electrical supply systems. These sophisticated devices are engineered to efficiently manage and distribute electrical power across various circuits within a building or facility. By segmenting the power feed into subsidiary circuits, panel boards facilitate the controlled distribution of electricity, making it possible to supply power to different areas and devices independently.

Core Functionality

The primary function of a panel board is to divide a single electrical power feed into multiple subsidiary circuits. This division is achieved by using individual circuit breakers or fuses for each circuit housed within a standard enclosure. The enclosure not only provides physical protection but also ensures that the components within the panel board are organized and accessible for maintenance and monitoring.

Protective Measures

One of the critical aspects of a panel board’s functionality is its ability to protect the electrical system from potential hazards such as overloads or short circuits. Overloads occur when a circuit draws more power than it is designed to handle. In contrast, short circuits are caused by a direct connection between two points of different voltage without any resistance. To prevent these dangerous conditions, panel boards are equipped with protective devices:

- Fuses: These devices are designed to melt and sever the circuit when the current flow exceeds a specified limit, preventing excessive current from causing damage.

- Circuit Breakers: Unlike fuses, circuit breakers can be reset after tripping. They automatically interrupt the flow of electricity when they detect an overload or short circuit, protecting the wiring and preventing fires.

Ensuring Operational Safety and Efficiency

By integrating these protective mechanisms, panel boards ensure the operational safety of the electrical system. They prevent physical damage to the wiring and connected devices and mitigate the fire risk, safeguarding property and lives. Additionally, panel boards contribute to the overall efficiency of the electrical system. By allowing for the independent control of different circuits, they enable the effective management of electrical loads, reducing energy waste and optimizing power distribution.

Types of Panel Boards

Panel boards are integral to electrical distribution systems and are designed to manage and safeguard electrical circuits. Their types are tailored to diverse requirements and applications, ranging from residential homes to large industrial complexes. Understanding the distinctions among various panel boards is crucial for selecting the appropriate type for specific electrical distribution needs.

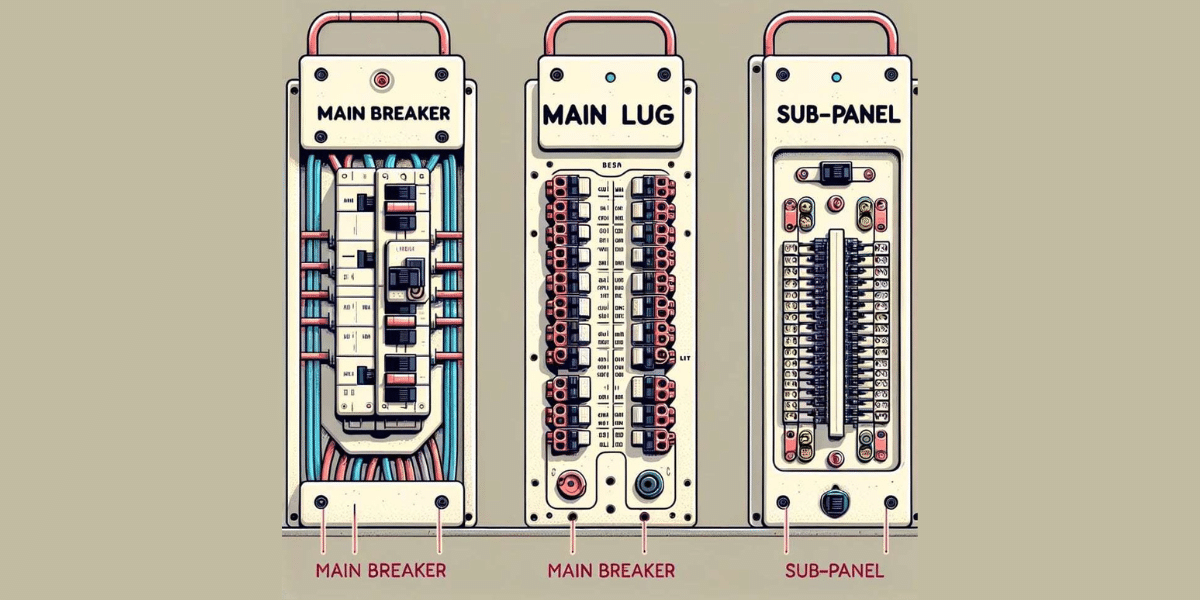

Main Breaker Panels

Overview: Main breaker panels are the cornerstone of home and commercial electrical systems. They feature a large main breaker that serves as the primary control point for the electricity supply to all circuits within the panel. This main breaker allows the immediate cessation of power to the entire system, a critical feature in emergencies or during maintenance.

Functionality and Safety: Including a main breaker provides a layer of safety by enabling the quick and complete shutdown of electrical power. This capability is essential for preventing damage during power surges, addressing electrical faults, or when electrical work is needed. The main breaker also acts as a primary disconnect, ensuring power can be safely managed and controlled.

Applications: Main breaker panels are widely used in residential and commercial settings. They are particularly suited to applications where centralized control and safety are paramount. These panels are also used in scenarios where future expansion of the electrical system is anticipated, as they allow for easy integration of additional circuits.

Main Lug Panels

Overview: Main lug panels offer a slightly different configuration from their main breaker counterparts. Power lines feed directly into lugs in these panels, and there’s no single overarching breaker at the panel’s entry point. Instead, they are typically connected to an upstream main breaker, often in a separate enclosure or a larger main panel.

Functionality and Flexibility: The absence of a built-in main breaker in main lug panels necessitates an external means of circuit protection, usually provided by the upstream main breaker. This setup offers flexibility in distribution system design, allowing these panels to function effectively as secondary or sub-panels that distribute power to specific zones or circuits within a property.

Applications: Main lug panels are commonly employed as sub-panels in larger buildings, industrial settings, or complexes where electricity is distributed from a primary panel to various secondary locations. They are ideal for areas that require localized distribution of power without the need for a main breaker at each distribution point.

Sub-panels

Overview: Sub-panels are smaller panel boards that act as offshoots from the main panel. They do not possess a main breaker but are protected and controlled by a breaker within the main panel. Sub-panels facilitate the extension of power distribution to remote areas of a property, segmenting the electrical supply into manageable zones.

Functionality and Distribution: The system enhances efficiency and safety by dividing the electrical load across multiple sub-panels. Each sub-panel can be tailored to its specific location needs, allowing for customized circuit management and easier troubleshooting.

Applications: Sub-panels are invaluable in multi-story buildings, large homes, detached garages, workshops, or outbuildings, providing localized control and power distribution. This arrangement simplifies wiring, reduces load on the main panel, and enhances overall electrical system manageability.

Installation Considerations

Installing a panel board involves careful planning to ensure safety and compliance with electrical codes. Key considerations include choosing a location that is easily accessible, protected from environmental hazards, and provide enough space for future expansions or maintenance. Professional installation by a licensed electrician is crucial to adhere to safety standards and regulations.

Maintenance and Safety

Regular maintenance, including inspection and testing of panel boards, is essential to prevent electrical accidents and ensure system reliability. Safety precautions, such as using personal protective equipment and adhering to lockout/tagout procedures, are vital for avoiding injuries during maintenance activities.

Uses and Applications

Panelboards are used across various settings, from residential homes to commercial buildings and industrial facilities. They enable efficient power distribution, easy circuit management, and enhanced safety by protecting against electrical hazards.

Future Trends in Panel Board Technology

Advancements in technology are paving the way for more intelligent, more efficient panel boards. Innovations such as modular designs, integrated monitoring systems, and compatibility with renewable energy sources are enhancing the functionality and sustainability of panel boards.

Conclusion

Understanding panel boards is crucial for anyone involved in the electrical field, from professionals to enthusiasts. With their ability to distribute and manage power safely and efficiently, panel boards are foundational to modern electrical systems.

Published By: Aize Perez