Introduction to GD&T

Geometric Dimensioning and Tolerancing (GD&T) is an essential part of engineering design and manufacturing, offering a standardized method for defining and communicating the geometric requirements of mechanical parts and assemblies. Traditional dimensioning methods often fall short in capturing the full geometric requirements of a part, leading to ambiguity and errors in manufacturing. The GD&T course addresses these shortcomings by providing a comprehensive way to define part geometry, ensuring that parts are manufactured to meet functional requirements accurately.

Key Concepts of GD&T

Overview of Geometric Symbols

GD&T uses a set of symbols to communicate specific tolerancing requirements on engineering drawings. Understanding these symbols is fundamental to interpreting design specifications accurately. Some common symbols include:

- Straightness (→)

Straightness (→) indicates a line element’s straightness tolerance.

- Circularity (∘)

Circularity (∘) specifies the roundness tolerance of a circular feature.

- Profile of a Line (∣∣)

Profile of a Line (∣∣) defines the tolerance zone within which the line profile must lie.

Datums and Their Significance

Datums are reference points or surfaces used to establish the coordinate system for dimensional measurements. They ensure consistent measurement reference across multiple parts. Understanding datums is crucial for correctly interpreting GD&T requirements.

Examples of Datums Include: Tolerance Zones

Tolerance zones define the allowable variation for a given dimension or feature. They can be cylindrical, spherical, or planar depending on the geometric control being applied. Tolerance zones ensure parts are within acceptable limits while still allowing for functional interchangeability.

GD&T Standards and Guidelines

Overview of ASME Y14.5 Standard

The ASME Y14.5 standard is a widely used standard for GD&T in the United States. It defines the symbols, rules, and conventions for dimensioning and tolerancing. Familiarity with this standard is essential for anyone working with GD&T.

Other Relevant Standards and Guidelines

While ASME Y14.5 is predominant, other standards such as ISO 1101 and ASME Y14.41 provide additional guidelines for specific applications. It’s important to be aware of these standards and their differences to ensure compliance with industry requirements.

Compliance and Practices

Adhering to GD&T standards and stellar practices is crucial for effective communication and manufacturing efficiency. Compliance ensures that parts are produced to the desired specifications, reducing errors and rework. Premier practices include clear and concise drawing documentation, proper use of symbols, and thorough tolerance analysis.

Dimensioning Practices

Types of Dimensions

There are various types of dimensions used in engineering drawings, each serving a specific purpose:

Size Dimensions: Specify the size of a feature.

Location Dimensions: Define the position of features relative to each other or to a datum.

Form Dimensions: Control the shape of features, such as flatness or straightness.

Orientation Dimensions: Specify the angular relationship between features.

Correct Application of Dimensions

Properly applying dimensions ensures that parts are manufactured to the intended specifications. Dimensions should be clear, unambiguous, and located where they are easily measured. They should also consider manufacturing processes and inspection methods to ensure practicality.

Case Studies

Real-world case studies illustrate the importance of proper tolerancing methods and the consequences of inadequate tolerancing. These examples demonstrate how tolerance analysis can prevent costly errors and ensure product quality.

Datums and Datum Systems

Definition and Purpose of Datums

Datums are reference points or surfaces used to establish the coordinate system for dimensional measurements. They provide a consistent reference for interpreting GD&T requirements and ensure parts are manufactured to the correct specifications.

Application of Geometric Controls

Geometric controls are applied using feature control frames on engineering drawings. These frames define the type of control, tolerance value, and datum references for each feature.

Examples of Geometric Control Application Scenarios

Real-world examples demonstrate how geometric controls are used to specify the requirements for features such as holes, shafts, and mating surfaces. These examples illustrate the practical application of GD&T principles.

Feature Control Frames

Interpretation of Feature Control Frames

Feature control frames communicate the geometric requirements for individual features on an engineering drawing. Understanding how to interpret feature control frames is essential for accurately manufacturing and inspecting parts.

Specifying Tolerances

Feature control frames specify the type of geometric control, tolerance value, and datum references for each feature. Properly specifying tolerances ensures that parts meet the intended design requirements.

Examples of Feature Control Frames in Practice

Real-world examples demonstrate how feature control frames are used to specify tolerances for features such as slots, tabs, and gear teeth. These examples provide insight into the application of GD&T principles in engineering design.

GD&T in Practice

Case Studies

Case studies demonstrate real-world applications of GD&T principles and the benefits they provide in terms of quality, cost savings, and efficiency. These examples highlight how GD&T is used in various industries, including automotive, aerospace, and manufacturing.

Challenges and Solutions

Implementing GD&T can present challenges, such as interpreting complex drawings, managing tolerance stack-ups, and ensuring compliance with standards. Understanding these challenges and implementing effective solutions is crucial for successful GD&T implementation.

Tips for Success in a GD&T Course

Study Strategies and Resources

Effective study strategies, such as practicing with sample problems, utilizing textbooks and online resources, and seeking guidance from instructors or peers, can help you grasp GD&T concepts more efficiently.

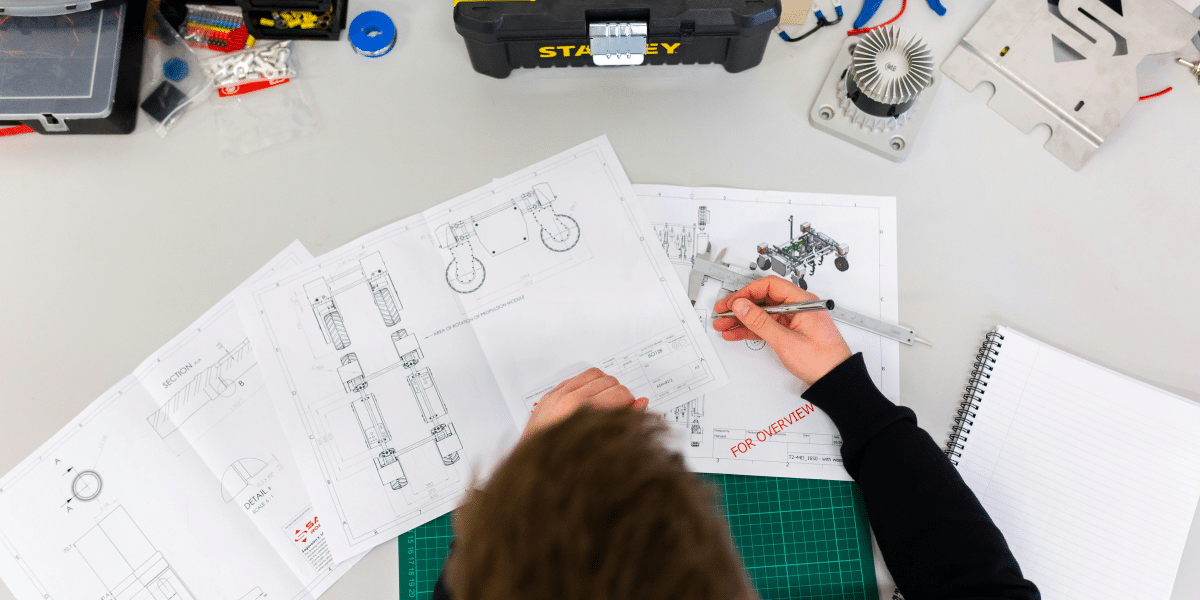

Practical Exercises and Projects

Engaging in practical exercises and projects allows you to apply GD&T principles in real-world scenarios, reinforcing your understanding and skills. These exercises can include creating engineering drawings, performing tolerance

stack-up analysis, and conducting GD&T inspections.

Final Remarks

Geometric Dimensioning and Tolerancing (GD&T) is a fundamental aspect of engineering design and manufacturing, providing a standardized language for communicating design intent and specifying tolerances. This comprehensive guide has covered the key concepts of GD&T, including geometric symbols, datums, tolerance zones, and geometric controls.

Published by: Khy Talara